TYPHOON 1

Features:

- Electric charging system on engine.

- Shock absorbing pads that help keep damaging vibration to an absolute minimum.

- Direct-drive blower, eliminating the need for belts.

- Positive displacement, high volume, rotary blower with corrosion resistant silencer.

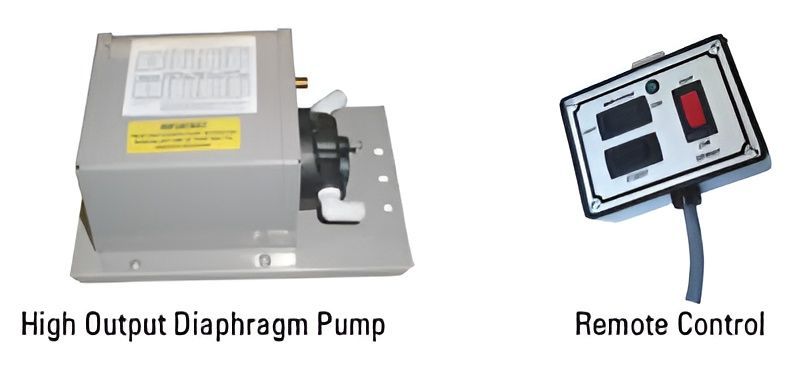

- Remote formulation and flush on/off control.

- Welded tubular-steel frame.

- No chemical formulations flow through the vehicle cab.

- Rugged, translucent, cross-linked polyethylene tanks that resist vibration damage and corrosion for maximum durability. Easily removed for cleaning. All components that come in contact with formulation are corrosion resistant.

- Liquid-filled air pressure gauge for monitoring nozzle air pressure.

- Electric stainless steel solenoid valves.

- Remote Choke Control:

Electric on Typhoon I™ with gear pump.

Mechanical on all others.

- Heavy-duty 12 volt DC battery.

- Limited 2-year warranty.

- 3 types of pumping systems:

- Diaphragm pump (Triple Typhoon)-- the diaphragm pump can produce the larger flow rates (and thus the Larger droplets) necessary for larvaciding and Barrier spraying

- Stainless gear pump with remote flush control.

- FMI ceramic piston pump with carbon cylinder.

The world's leader in aerosol applicator technology, Curtis Dyna-Fog, introduces the Typhoon I ULV™. This machine has been engineered to be rugged, compact unit with the same high standard of uniform droplet formulation as our other models. The high quality of its components ensures low maintenance cost combined with an appealing purchase price.

With a selection of three advanced, high performance pumping systems, this proves that the Typhoon I ULV™ is an outstanding value. Ease of operation and user-friendly features clearly define the technology that only Curtis Dyna-Fog, with over thirty years of experience, can deliver.

A Dyna-Fog Typhoon I ULV™ is an effective way to reduce insect borne diseases like malaria, dengue fever and encephalitis, and to control environmental pests.

Whether a new user or a long-time user of Curtis Dyna-Fog Applicators, you will appreciate the convenient location of all components and the corresponding attention to detail.

SPECIFICATIONS: DIAPHRAGM PUMP, GEAR PUMP, FMI PUMP

| Formulation Output | Diaphragm pump – 0-128 oz/min; 0-3.8 Liters/Min Gear pump – 0-20 oz/min; 0-600 ml/min FMI pump – 0-18 oz/min; 0-532 ml/min |

|---|---|

| Droplet Size | 90% of droplets below 20 microns VMD |

| Engine | Kohler 9.5 Hp (277 cc), 4-cycle, OHV, electric start. Optional Honda 10.5 Hp (344 cc), 4-cycle, OHV, or Yanmar diesel |

| Blower | High volume, positive displacement, rotary type; 8.5 psi @ 2750 rpm; 12 psi (0.82 bar) 205 cfm (5.8 Cubic meters/min) |

| Pump Systems | Diaphragm pump - high volume, corrosive resistant Gear pump - stainless steel, magnetically coupled FMI - ceramic piston with carbon cylinder Optional radar syncroflo automatic control with digital display |

| Nozzles | High efficiency single nozzle, adjusts 360 degrees, removable for cleaning |

| Gauges | Digital Tachometer/Hourmeter for engine; liquid filled pressure gauge for nozzle boom pressure |

| Weight | Empty: 297 lbs; 135 kg. Full: 412 lbs; 187 kg |

| Fuel Tank | 1.8 gallons; 7 liters; with a gauge |

| Formulation Tank | 15 gallons; 57 liters; with lockable cap |

| Flush Tank | 1 gallon; 3.8 liters |

| Dimensions | 41.5 x 29 x 32 inches; 105 x 74 x 81 cm (L x W x H) |

| Shipping Data | 48 x 40 x 39 inches; 122 x 100 x 99 cm (L x W x H) 415 lbs; 188 kg 42.8 cubic feet; 1.2 cubic meters |

Optional Extras

- Boom for full 360° horizontal and vertical adjustment.

- Spray hour-meter.

- Waterproof machine cover.

- Sewer attachment kit.

- Remote spray head.

- Automatic engine idle back